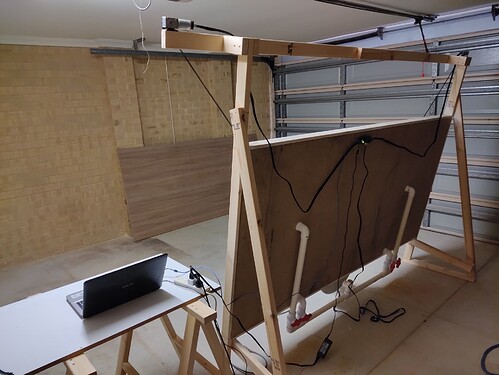

I thought I would share my suction bed design that I have been working on.

I will be using my Maslow for cabinetry (large parts) so was hoping not to use tabs on my parts and create a suction system that can still hold parts onto the spoil board after cutting through.

I cheated a little as I used the cnc at work to create the suction bed and spoil board sheets as these would be very time consuming done by hand. Even on our Weeke machine it still took over an hour to machine the suction bed board but if you had more time to spare, this could be done with a hand router and stops.

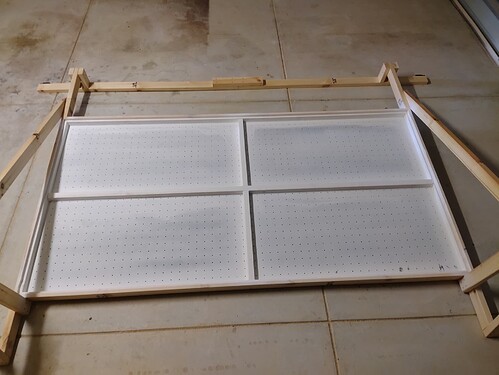

I used 32mm PVC pipe and split the internal suction area into 4 quarters so I can shut down sections not needed using the valves.

Both the suction board and rear of unit were completely sealed using an acrylic sealer to stop any leaks.

Rubber seals were used to separate the 4 quarters on the face of the suction board

First test just putting a vacuum into the rear line and it works amazing. I can’t physically remove the board while the suction is on.

So I am just waiting for some pipe and connectors to arrive so I can finish the suction line and fit a cyclone. Also waiting on a new router to finally trial some cutting. Will post the results here.

Cons -

- This frame has become very heavy. Was originally looking at putting on castors but not so sure now.

- Doubt it will hold small parts as the cuts move through the full thickness of the board allowing the suction to escape. Be interesting to see in action.

Thanks